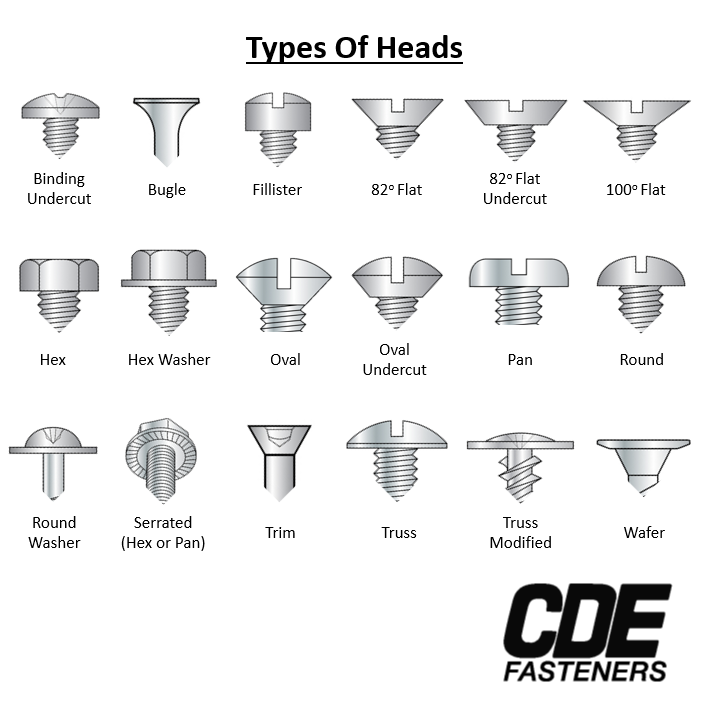

The "Head" of a fastener is the area of the screw or bolt in which the "Drive" of the fastener is contained. This geometric feature is the clamping point between fastener and the work piece in which it is being installed. The head is a critical feature in the Anatomy of a Screw and plays a large role in How to Measure the Length of a Screw or Bolt. Often after installation, the head is the only part of the fastener you can visually see. Some sit flush to the surface, and some are proud. Certain types of fasteners, such as hex heads and hex washer heads, have a head that can be used as the driving feature for turning the fastener using a wrench or socket. Users commonly confuse the term "Head" for "Drive" particularly when dealing with a Phillips or Slotted screw which are driven by a Phillips or Slotted head screwdriver or a "bit." This is in fact incorrect; the head of a fastener is the area above the shank or threaded region of a fastener and often has the largest diameter.

When it comes to fasteners, there are numerous different head types. Each head type has a different common use and is better for some applications than others. Not all heads are available or compatible with all drives. There are certain circumstances in which a particular head is not plausible or available with a particular drive. Throughout the History of Fasteners, many different styles of heads have been used for various reasons and applications. In this article we aim to point out the commonly used applications and a brief history of how these various head styles have come about.

Binding Undercut – commonly used in electrical applications. The undercut is a channel which allows for the incorporation of electrical wires underneath the head of the screw for wire connections. This secure connection increases electrical conductivity due to the larger surface contact area. This head can be used with a variety of drives, including Phillips, slotted, and combination drives. To get a better understanding of this design please take a look at this spec sheet. The Binding Undercut is often abbreviated BIND.

Bugle – Named after the bugle horn, this head is commonly used in both wood decking and drywall screws and utilizes a countersunk head style. Typically used in "softer" material the tapered wedge moves material out of the way for a self made countersink without the need for additional tools. This wedge can cause material to rise above the workpiece causing the fastener or material to be proud when fully installed in a workpiece in some cases but can be installed faster than a flat head. A bugle head is wider than a flat head and applies more downward clamping force due to a flat face under its head. The bugle head can be used with Phillips, slotted, and 6 Lobe and is often abbreviated BGL.

Fillister – This deep slotted head has a higher profile than that of either round or pan heads. This head can be used with a Phillips or slotted. Fillister is often abbreviated FIL.

82° Flat – This version of a flat head is considered the standard version of a flat head in inches (90° Flat in metric). Flat heads allow for a “flush” or smooth finish in application, making them ideal for aesthetic or decorative applications. A countersunk head style. Typically found in both metal and wood applications. This head can be used with a variety of drives, including Phillips, Slotted, 6 lobe, Pozi and Square drives. Unlike the Bugle Head, a flat head requires pre-drilling before installation. Flat Head often abbreviated FL.

82° Flat Undercut – Similar to a standard flat head, the undercut allows for a smaller countersunk area of and is used for shallower applications where there is a reduction in area for the head to be sunk. Commonly used in thin sheet metal applications; particularly in door hinges. There is no metric standard for a flat undercut head. This head is often abbreviated U/C FL.

100° Flat – Utilizes a 100° angle as opposed to a standard 82°, This head is often used for thinner material without sacrificing surface area contact due to a larger head diameter than that of the 82° Flat Head. The 100° Flat is also available in a 100° Flat Undercut option for machine screws in inches. 90° Flat is the only Flat Head available for metric. The Flat head is often abbreviated 100° FL.

Hex – Most commonly found in “Bolts.” Hex heads allow for a large amount of torque or force to be applied when driven due to the external surface of the hexagonal (six sided) head for contact while driving. This drive requires a wrench or socket for application. Often called an Indented Hex Head and abbreviated IND HEX. Hex Cap Bolts have a washer bearing surface underneath the hex head to allow it to remain perpendicular when tightened.

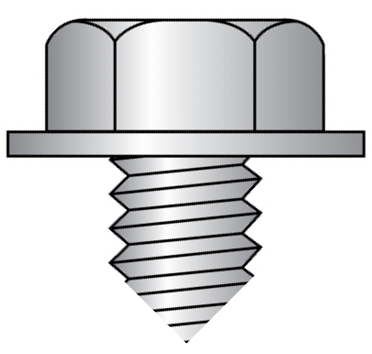

Hex Washer – Growing in popularity, this head style is very similar to the hex itself. A washer style flange is attached to the bottom of the hex head; this allows for larger bearing surface contact and distributed load of fastener. This washer prevents the wrench or socket from marring (disfigure the appearance) of the workpiece surface. These are often used in high speed assemblies. Secondary drives like combination, slotted, and Phillips can be recessed into the hex portion of the head allowing easier serviceability and maintenance for the end product. Often abbreviated HWH.

Hex Washer – Growing in popularity, this head style is very similar to the hex itself. A washer style flange is attached to the bottom of the hex head; this allows for larger bearing surface contact and distributed load of fastener. This washer prevents the wrench or socket from marring (disfigure the appearance) of the workpiece surface. These are often used in high speed assemblies. Secondary drives like combination, slotted, and Phillips can be recessed into the hex portion of the head allowing easier serviceability and maintenance for the end product. Often abbreviated HWH.

Oval – Similar to the flat head, but with a domed oval section added on top. The Oval head sits proud of the workpiece when seated giving a finished and aesthetic look. The oval dome section of this fastener is not included in the screws length measurement and is instead measured at the transition line. This required the use of a predrilled or stamped countersink. Commonly used for switch covers, knobs, and handles. This head can be used with a variety of drives, including Phillips, slotted, and 6 Lobe drives. Often abbreviated OVAL or OVL.

Oval Undercut – Similar to that of the standard Oval Head with the addition of an undercut. The undercut assists in applications with shorter countersunk depths. Measured identically to the oval head similar to the flat head, but with a domed oval section added on top. Popular in electrical outlet covers. Oval Undercut is abbreviated U/C OVAL or OVL.

Pan – This is the most common "rounded" head style. A relatively small profile and commonly used in applications such as mounting brackets or hardware. A pan head can be substituted in most applications for round, truss or binding heads due to the pan head having a smaller outer diameter. Pan head machine screws are common among household appliances, both in consumer and industrial goods. The pan head can be used with a variety of drives including Phillips, slotted, 6 lobe, and combination drives. When fully seated, the Pan Head sits proud of the workpiece. The pan is a stronger evolution of the round head. Simply abbreviated PAN.

Round – Often used as an alternative to the oval head style without the need for countersinks and is a versatile option that can be used in a variety of applications. This style is sometime preferred over a pan head because it provides a finished look but has shrunken in popularity over recent years. Commonly used in electrical applications and provides a finished / aesthetic look. This head can be used with a variety of drives, Phillips, slotted, U Drive, and combination drives. Often abbreviated RD.

Round Washer – Similar to round heads, a washer style flange is attached to the bottom of the round head. The washer allows for more distributed loading and less stress on the head of the fastener. Compared to a round head the washer also provides a relatively finished aesthetic look. Often abbreviated RD WASHER.

Serrated (Hex Washer, Pan, and Truss) – Not a head style itself, but serrations can be added under the head of hex washer, pan, and truss heads. The serrations under the head are intended to prevent loosening and backing out in high vibration applications. This addition is often abbreviated SRT.

Trim - Similar to that of a flat head, this option is often used for finishing work as it has a narrower head. The slimmer head is designed to make the fastener less visible after installation. A Trim head can be used with a variety of drives, including Phillips, square, and 6 Lobe drives. Commonly found in various woodworking projects and carpentry. Simply abbreviated TRIM.

Truss - Also known as a “mushroom” head this head allows for an increase in bearing surface, allowing for greater clamp force while maintaining a lower profile than most other round, larger bearing surface screws. Weaker than pan or round heads but preferred in applications where minimal clearance exists above the head. This head can be used with a variety of drives, including Phillips, slotted, 6 Lobe, and combination drives. Commonly used in woodworking applications. Commonly abbreviated TR.

Truss, Modified - Like the truss head with an even larger head diameter and lower profile than that of the standard truss. A washer style flange is attached to the bottom of the Truss head; this allows for higher bearing surface contact. Offers low clearance and an extra large bearing surface. Commonly found on self drilling screws when attaching metal lathe to metal studs. Commonly abbreviated MOD TR.

Wafer - commonly found in Self-drilling screws. The wafer head is similar to that of a flat head, which utilizes a countersink but with the addition of a bearing surface for clamping. This head can be used with a variety of drives, including Phillips, slotted, 6 Lobe, and combination drives. Designed to sit flush with the workpiece surface to distribute the load. Used often in wood and softer materials. Commonly abbreviated

CONCLUSION:

When it comes to choosing the correct head for your fastener needs, there are many different options and applications to choose from. However, using the information in this guide, choosing the correct head style will hopefully be easier than before. Whether you are looking for a low-profile countersunk screw like that of the flat head or a smooth decorative finish of an oval head. Choosing the right fastener head type is crucial for the success of any project. The head type can affect the length, strength, aesthetics, and functionality of the screw or bolt in various applications. By understanding the different types of fastener heads and their applications, you can make an informed decision on which head type is best for your project. Now Let's Get Building! ®