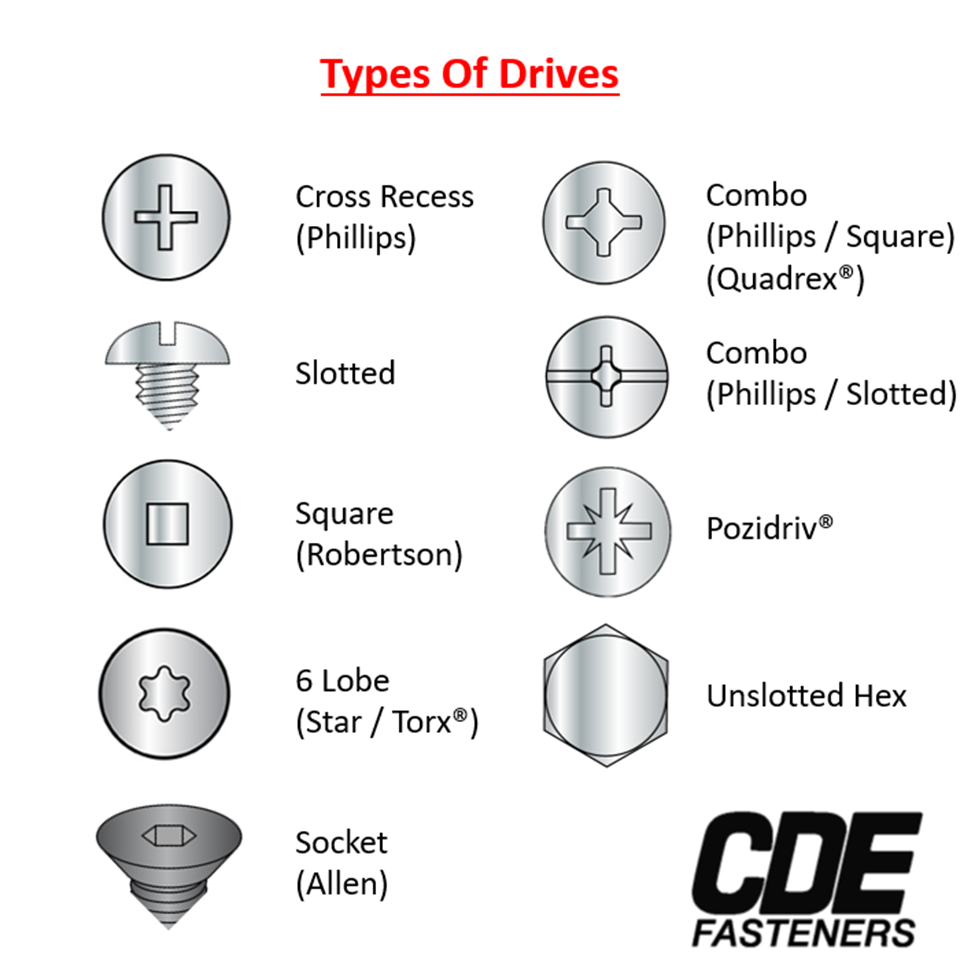

The "Drive" of a fastener is the area of the screw or bolt in which a tool is used to turn the fastener, such as a screwdriver, bit, socket, or wrench. This geometric feature, on the fastener, DRIVES the screw, bolt or anchor to its final position.

The "Drive" of a fastener is the area of the screw or bolt in which a tool is used to turn the fastener, such as a screwdriver, bit, socket, or wrench. This geometric feature, on the fastener, DRIVES the screw, bolt or anchor to its final position.

Throughout the History of Fasteners, many different styles of drive have been used for various reasons and applications. Some were invented to improve existing designs, others to allow for use with various tools. When selecting the right fastener for the job, how do you know where to start? We aim to answer that question and provide some backstory on how the various fastener drives came about. Drives are often confused with the head of a fastener. A Phillips "Drive" is often mistakenly called a Phillips "head" screw but that is not the correct way to identify a fastener. As shown in our other article "Anatomy of a Screw or Bolt" the drive is located within the head of the fastener but, is a different attribute and geometric feature than the "head".

Not all drives are available or compatible with all heads. There are certain circumstances in which a particular drive is not plausible or available with a particular head. Below is a list of the most commonly used drives today. Other fastener drives do exist and can be found in various applications around the world, but for this article we will omit security drives and other odd specialty drives.

Slotted – Designed to be used with a flat blade (commonly referred to as “flathead screwdriver/bit.” This is the oldest drive style still commonly in use to this day. However, this design tends to experience slip out and does not support higher torque operations. Historically, the military used slotted drives because soldier's fingernails could be used loosen or tighten. This drive is commonly abbreviated as SL or SLT.

Cross Recess (Phillips) often considered the most common drive for a screw/fastener. Invented in the early 1930’s by Henry Phillips, this drive is designed to intentionally "cam out" (slip, strip, slide), contrary to common complaint, at high torque resistance so to prevent overtightening. The cross-recess drive is one of the first alternative options to slotted drives. This drive is commonly abbreviated as PH.

Combo (Phillips / Slotted) – This combination drive was developed to allow for a user to utilize either the Slotted or Cross Recess bits on the head of the fastener as a means of assembly and disassembly. Using this geometric feature, an end user can have options for how to drive the screw. This combination drive is commonly abbreviated as PH/SL.

Pozidriv® – Patented in 1962, this drive is considered an improvement on the standard Cross Recess (Phillips) design. This design allows for a greater resistance to cam out due to additional slots positioned 45° from standard cross recess patterns. Pozidriv® requires a specially designed Screwdriver/Bit with a blunted tip instead of the traditionally pointed driver. Unfortunately, a Cross Recess driver can be used to install fasteners with this drive but can cause increased cam out and the rounding of edges of the recess. This drive is commonly abbreviated as Pozi, PZ and PSD.

Square (Robertson) – Invented in 1908 by P.L. Robertson, a Canadian, designed to prevent the common occurrence of slotted drives slipping out while also preventing cam out seen by a cross recess. This decreased the assembly time of fasteners significantly while improving torque simultaneously. A square drive is commonly abbreviated as SQ or SD.

Combo (Phillips / Square) Quadrex® – This drive uses a specialized bit but has evolved to allow for use with both a square drive and cross recess (Phillips); providing a user with the flexibility to use either option for assembly. The square drive is nested inside of the cross recess (Phillips). This combination drive is commonly abbreviated as PH/SQ.

6 Lobe ("Star" / Torx®) – Invented in 1967 by Camcar Textron. Commonly referred to as a Torx® or "star" drive. This drive utilizes a 6-lobe design in contrast the 4 from a Phillips. A higher installations torque can be achieved and there is reduce slip out due to an increase in surface area contact. The drive can also engage faster with a bit as there are more angular mating positions making high speed assembly easier. This drive comes in various sizes that match to a specific sized driver. Commonly abbreviated as T6, T8, T10, etc. based on drive size used.

Unslotted Hex – This design is one of the only drives that utilized the external surface of the head itself to drive and turn the fastener. Commonly driven with a socket or wrench, the unslotted hex is measured by the width “across the flats” or from parallel walls on the head. Commonly abbreviated as USL or Hex. A Hex can also be a head style due to the external geometry. This allows flexibility, in that the external hex can contain a second internal drive like a Slot, Cross Recess, or Combo. A Hex Drive is typically good for high-speed assembly.

Socket (Allen) – Designed with an internal hex socket and required to be used with a specific tool or bit known as a hex key or “Allen wrench.” These heads are standardized to be used with various sizes of hex keys. Commonly referred to as Allen Key and is a registered trademark. The fastener industry refers to these as SOCKET screws. When working in inches, Socket Screws, are most commonly an alloy steel (stronger than Grade 8) or made of Stainless. In Metric, the strength of socket screws are more varied.

When it comes to choosing the correct drive you also need to keep in mind that most of these drives come in variety of different sizes for bits. CDE Fasteners also has bits available for purchase directly on our website. For example, 6-lobe drives come in sizes often abbreviated in T-XX as well as different sized, Phillips (Crossed-Recess) in sizes 1, 2, and 3; various sizes in Sockets (Allen Keys), Square (Robertson) in sizes 0, 1, 2, and 3; External Drive Socket Wrenches, Pozidriv® in sizes 1, 2, and 3; and Slotted based on screw diameter . Ensure that when you are choosing the drive you desire for your fastener you also have the correct size bit available for your application.

CONCLUSION:

When it comes to fasteners, there are various options when deciding the right drive for the job. Whether you intentionally want a driver to cam-out to reduce over torquing or having the option to use a socket to drive a fastener with the external surface of a hex head, there are fasteners for that! Different drives allow the user the flexibility to decide how a fastener can be assembled or disassembled. Knowing how different drives perform and the appropriate application of each drive is important. Your design can be for high-speed assembly, or serviceability/maintenance, fine tune adjustment, homeowner ease of use, or even purposely chosen to make disassembly difficult. Your preferred drive and how you came to that decision will be different per your application, product, project or simply the tool in your toolbox. Your assembly tools available, whether manual, pneumatic, or electric influences these decision.

Now Let's Get Building! ®