The thread of a fastener is defined as the helical spline or splines which spiral down the shank of the fastener. This is the part of the fastener which does the work involved in tightening and locking parts together (Where "mechanical advantage" occurs.) The rotation of the threads causes linear motion (up and down movement) of the screw, nut, or bolt relative to a fixed part. Different thread styles are designed and optimized for different applications. The threaded region of a screw or bolt is part of a larger system referred to as the "Body" and "shank" as defined in our previous blog "The Anatomy of a Screw".

The thread of a fastener is defined as the helical spline or splines which spiral down the shank of the fastener. This is the part of the fastener which does the work involved in tightening and locking parts together (Where "mechanical advantage" occurs.) The rotation of the threads causes linear motion (up and down movement) of the screw, nut, or bolt relative to a fixed part. Different thread styles are designed and optimized for different applications. The threaded region of a screw or bolt is part of a larger system referred to as the "Body" and "shank" as defined in our previous blog "The Anatomy of a Screw".

In the a breif history of fasteners, we discuss the 2 main units of measurements and standardizations created in the 1900s, [Unified Thread Standard (UTS) and ISO Metric (International Organization for Standarization)]. In the United States and Canada, the most common system for threads is the Unified (Inch) Screw Thread System. It is estimated that roughly 60% of screws in the United States use this system of threads. However, some industries have been adopted where the ISO Metric system is preferred. For example, the automotive Industry has been officially converted to the ISO Metric system. The ISO Metric System is used predominantly in almost every other country in the world. This blog aims to provide a basic understanding of the two major types of threads, how they are measured and some of the basic applications and uses they can be found in.

Basic Nomenclature:

A screw or bolt size is typically written. Diameter – Thread Pitch X Length.

Define your units. Are you working in Standard (UTS) or Metric (ISO)?

What Diameter?

When working in inches, UTS, if the diameter is under ¼”, instead of using fractions, a # (Number) system is used. #0 - #12 (these are broken down in increments of 0.0130”)

In metric, a Capital M is used to signify METRIC, and the diameter. This diameter is in millimeters (mm) even though it is written starting with a capital M.

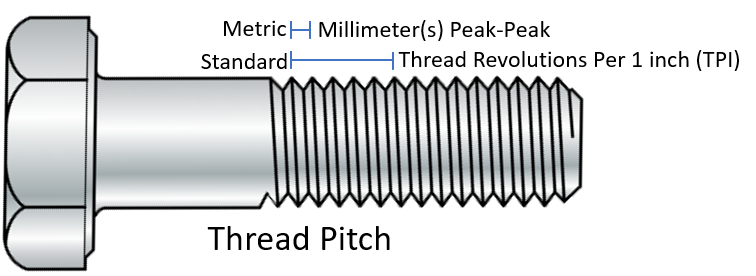

Now we can define Fastener Thread Pitch

UTS (inches) notes this as threads per inch (TPI). This denotes how many thread revolutions occur within one inch of the threaded region on the fastener.

Metric threads are measured by the distance from one crest to the next (Distance Peak - Peak) in mm (millimeters).

The measurement systems have pre-determined, standardized, thread pitches based on the diameter and STYLE.

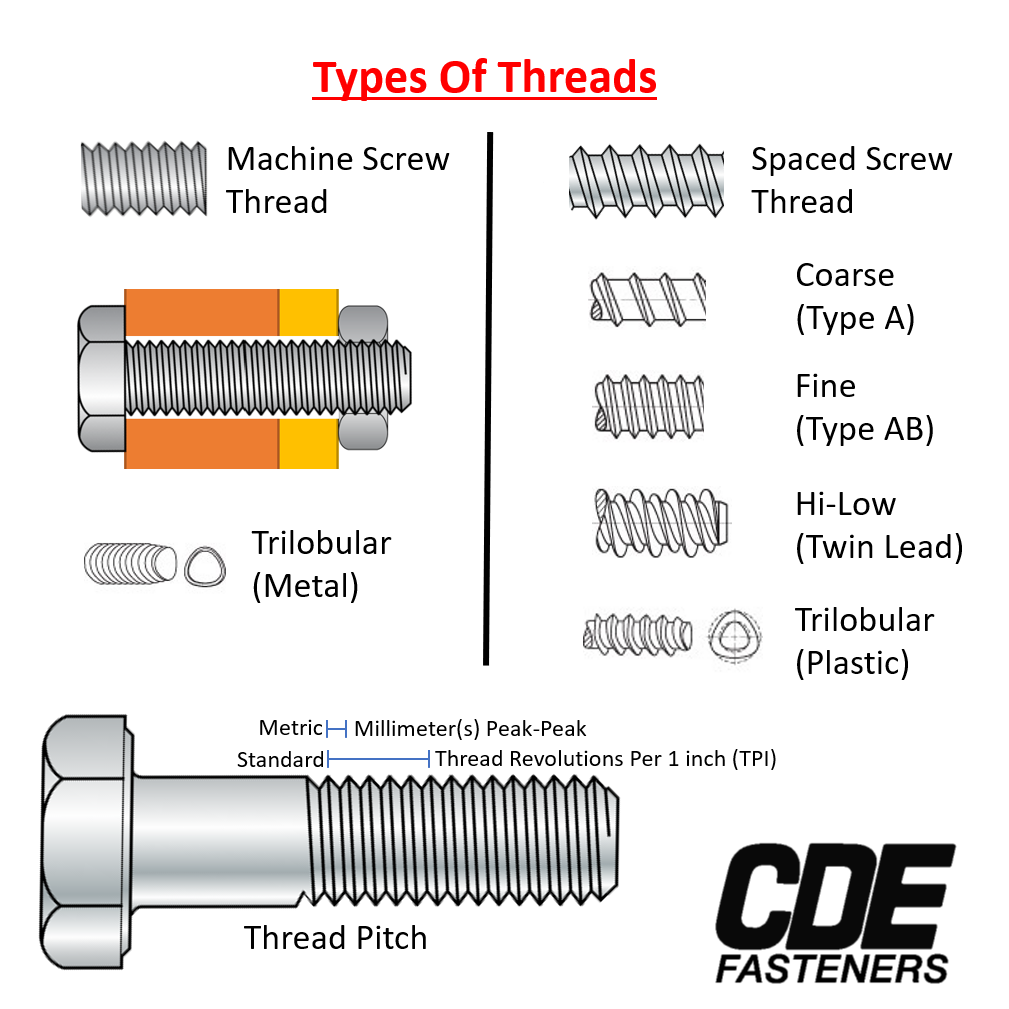

There are 2 major thread styles:

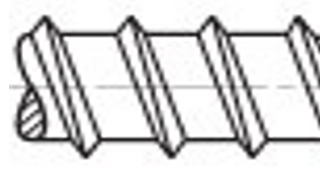

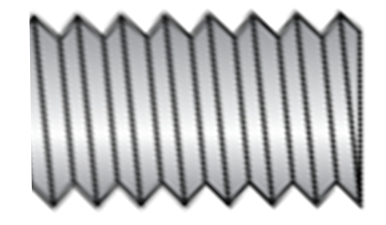

Machine Screw Thread - 60° thread angles designed to go into a TAPPED hole or mate with a threaded nut

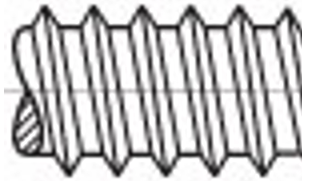

Spaced Screw Thread - have a gap or flat between threads and designed to go into holes WITHOUT threads.

Let's break them down.

Also referred to as 60° Screw Threads are designed to thread into a hole or nut that is pre-tapped to form a mating thread for that screw. Machine screw thread is the most common type of thread one interacts with daily as it used in applications where something is unscrewed and then tightened again or something which needs to be tightly torqued. Look at your common electrical outlet covers and fixtures, these are examples of machine screw threaded fasteners.

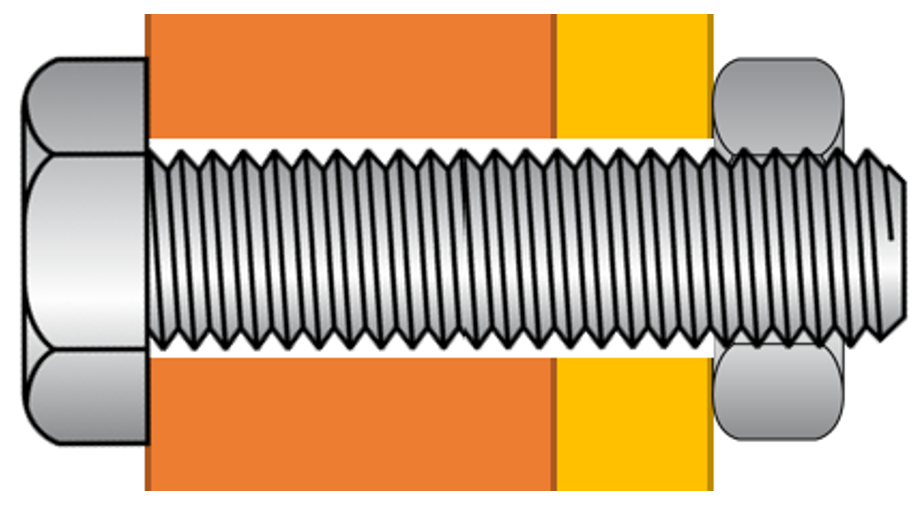

Whenever you see a nut and bolt, these are locked together with machine screw thread. The mating nut has a thread diameter and pitch to allow for appropriate engagement between the two parts of the assembly.

Whenever you see a nut and bolt, these are locked together with machine screw thread. The mating nut has a thread diameter and pitch to allow for appropriate engagement between the two parts of the assembly.

The 2 measurement systems have pre-determined values for each diameter based on the long history of fasteners and ease of machining the parts. They break down into Coarse and Fine Thread. In the unified thread standard (UTS, inches) these are sometimes referred to as UNC and UNF (Unified National Coarse and Fine). In the metric system, if the thread pitch is not called out in the sizing notation, then the part is automatically assumed to be coarse thread. Both coarse and fine threads have their own advantages. Coarse threads are less prone to stripping or cross-threading and are less likely to nick. Additionally, coarse threads are quicker to install and are less affected by plating build up due to the larger distance between threads. On the other hand, fine pitch threads have greater strength in both shear and tension for the same hardness and size, as they possess a larger cross-sectional area. They are also less likely to loosen due to vibration and are easier to tap into difficult and thin materials. Furthermore, fine pitch threads require MORE torque to reach the same pre-load as a coarse pitch thread.

An example of how thread pitch and diameter are designated in the UNC series format would be as follows: 1/4-20 (Diameter-Thread Pitch) describing a screw or bolt with 1/4" diameter and 20 full threads per 1" of threaded region. In the metric (ISO) system simply saying M8 diameter infers coarse thread, we then know the fastener is a M8-1.25 (Diameter-Thread Pitch). (In the metric system, sometimes the - is replaced with an x, but in general think Diameter - Thread Pitch X Length. A M8-1.0 would indicate a screw or bolt with an 8mm diameter and a 1 mm distance between one peak of thread to the next (fine thread). It is critical and mandatory for fasteners with a machine screw thread to be mated with either a nut or tapped hole with the exact same diameter and thread pitch.

Determine diameter in the appropriate units then look up thread pitch on the chart below:

Reviewing the table above, you can also notice that Inch and Metric parts ARE NOT interchangeable. There are small decimal differences between the two systems and even though close, these cannot be replaced with a similar fastener of the opposite units.

![]() - Trilobular Screw Threads - (Used for Metal) Thread Rolling/Forming Screws form their own thread in a ductile metal hole. Although these do not go into a PRE-TAPPED hole, these metal thread forming screws, also referred to by their brand name Taptite®, share a design of screws utilizing a machine screw thread pitch to tap its own threads in ductile metals. This is a unique version of a machine screw threaded fastener. The trilobular design utilizes the same thread pitch of a machine screw fastener but is not used in a pre-tapped hole. There are other differences as well in the thread, but the TPI units are the same. These METAL Trilobular thread styles use machine screw thread as they are attempting to make the untapped hole into a "tapped" or threaded one. You will see this in die cast screw bosses. The metal part is made in a mold, with untapped holes, or holes are dilled, then this Metal thread forming screw will cut machine screw type threads in, during the first installation. The trilobular design gives room for the material removed while forming the threads a place to stay and not clog jam the threads.

- Trilobular Screw Threads - (Used for Metal) Thread Rolling/Forming Screws form their own thread in a ductile metal hole. Although these do not go into a PRE-TAPPED hole, these metal thread forming screws, also referred to by their brand name Taptite®, share a design of screws utilizing a machine screw thread pitch to tap its own threads in ductile metals. This is a unique version of a machine screw threaded fastener. The trilobular design utilizes the same thread pitch of a machine screw fastener but is not used in a pre-tapped hole. There are other differences as well in the thread, but the TPI units are the same. These METAL Trilobular thread styles use machine screw thread as they are attempting to make the untapped hole into a "tapped" or threaded one. You will see this in die cast screw bosses. The metal part is made in a mold, with untapped holes, or holes are dilled, then this Metal thread forming screw will cut machine screw type threads in, during the first installation. The trilobular design gives room for the material removed while forming the threads a place to stay and not clog jam the threads.

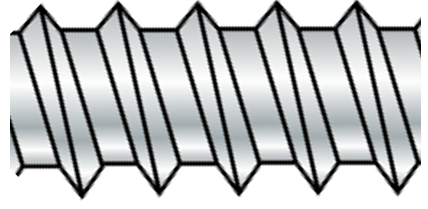

Unlike 60° threads, where the end of one thread is the start of the next corresponding thread, spaced threads are separated by a flat in their root between the end of one thread and the beginning of the next. Spaced threads are thread forming and "tap" the corresponding threads into a predrilled hole. These threads do not mate with a nut. Their thread pitch is always more coarse than machine screw thread. (The threads are SPACED further apart) Whenever there are no threads in a piece of wood, sheet metal, or plastic part, think SPACED thread.

Unlike 60° threads, where the end of one thread is the start of the next corresponding thread, spaced threads are separated by a flat in their root between the end of one thread and the beginning of the next. Spaced threads are thread forming and "tap" the corresponding threads into a predrilled hole. These threads do not mate with a nut. Their thread pitch is always more coarse than machine screw thread. (The threads are SPACED further apart) Whenever there are no threads in a piece of wood, sheet metal, or plastic part, think SPACED thread.

A common version of the spaced screw thread is called a self-tapping screw. These screws are often called "sheet metal screws" but do not need to be used purely in sheet metal. The tapping spaced thread design can be used in wood, plastic, and metal. Self-tapping screws / sheet metal screws are most often confused with self-drilling screws. Self-drilling screws have a drilling point on the tip of the shank that drills the necessary hole prior to tapping threads into a mating part. Like machine screw threads, spaced thread typically comes in coarse and fine thread. Below are some variations of the Spaced Screw Thread Design:

Self-Tapping Screws:

- Type A - Denotes Coarse Thread version of a self-tapping screw and was designed for self-starting in thin (.015" to .050" thick) metal or resin-filled plywood.

- Type AB - Denotes Fine Thread version of self-tapping screw and was designed for use in the thinner sheet metal commonly used today, particularly in appliances.

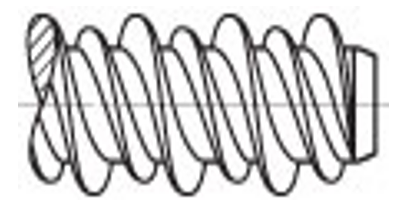

There are variations of spaced thread, where the threads are geometrically different, but the pitch is the same or some combination.

- High-Low Screw Thread - This thread design has a “Double Lead”. There are 2 different SPACED thread splines spiraling around the shank of the screw. One thread or “Lead” is higher than the other (Hense the name "High-Low"). This thread allows for an easier and faster installation due to the larger distance between threads allowing 1 turn (revolution) of the screw to move further into the workpiece. Concrete screws often share this similar thread design.

- Trilobular Screw Threads - (Used for Plastic) Thread Rolling Screws form their own thread in a plastic. Also referred to as Thread Forming Screws or by their brand name Plastite®, this design is ideal for plastics. Commonly used in housings for household appliances, assembly housings such as vacuums, power tools and kitchen products.

- Trilobular Screw Threads - (Used for Plastic) Thread Rolling Screws form their own thread in a plastic. Also referred to as Thread Forming Screws or by their brand name Plastite®, this design is ideal for plastics. Commonly used in housings for household appliances, assembly housings such as vacuums, power tools and kitchen products.

Conclusion:

Fastener threads come in two major types: machine screw threads and spaced screw threads. The threaded region of a fastener is part of a larger system referred to as the "body" of a screw, which contains threads and any unthreaded portion of the cylinder, as well as both the point and shank of a fastener. Threads are identified and categorized differently depending on the unit of measurement, with the Unified (Inch) Screw Thread System being commonly used in the US and Canada, while the ISO Metric system is used predominantly in other parts of the world. Coarse and fine pitch threads have their own unique advantages, and "Unified" fastener threads are measured in terms of how many thread revolutuions occur within one inch of the threaded region while "Metric" threads are measured in distance from one crest to the next, known as the "thread pitch." Understanding the distinct characteristics of fastener threads is essential when selecting the appropriate fastener for a specific application.

Now Let's Get Building! ®